No products in the cart.: $0.00

Capabilities

- Home

- Capabilities

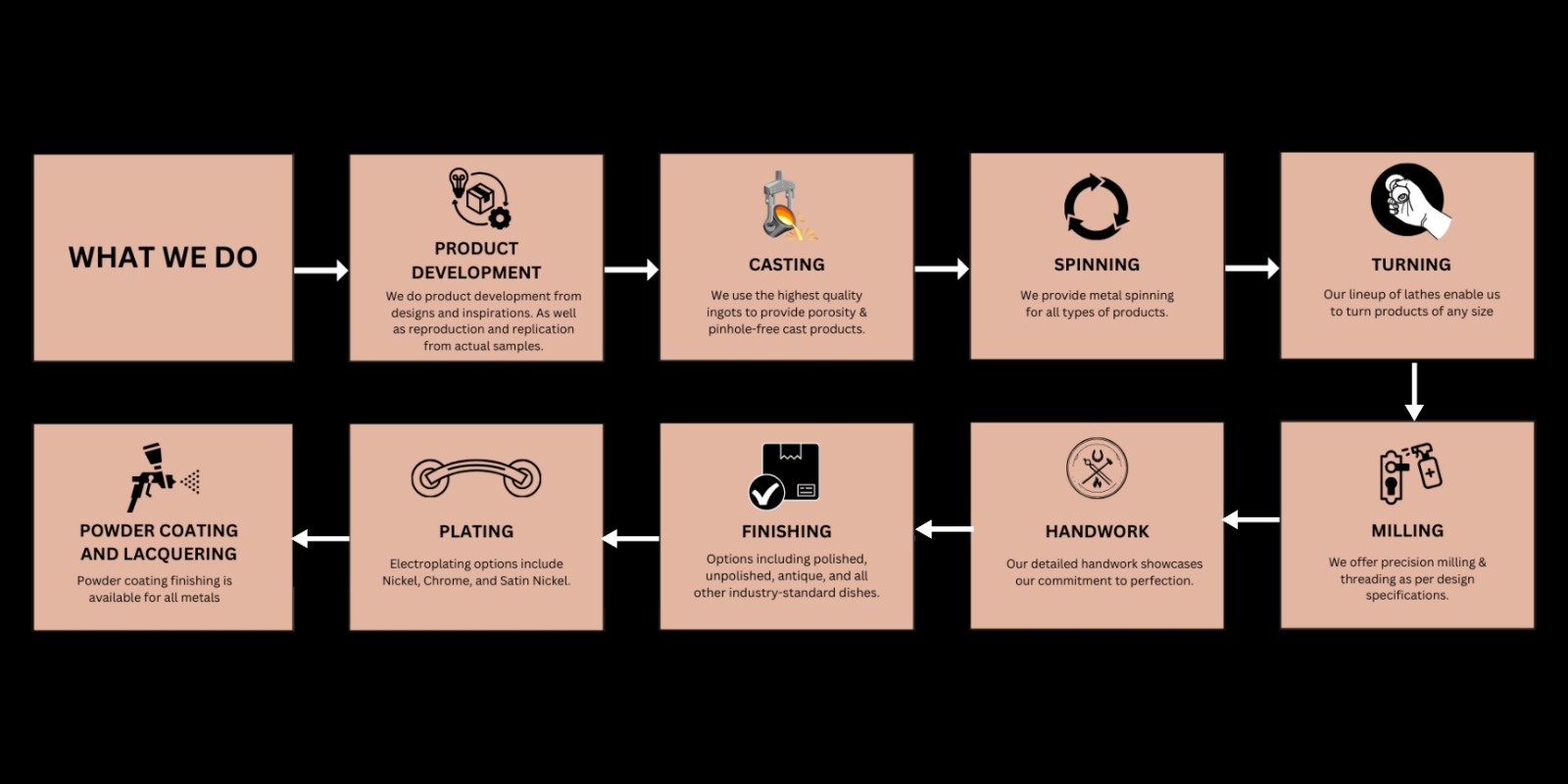

We pride of our 100% In-House production with the following facilities

- We take great pride in producing all of our goods in-house at the following sites.

- Lathe, grinding, milling, drilling, taping, lancer, and power press equipment; casting (sand and gravity)

- Forging machine with a variable load capacity of up to 400 tons

- Electrostatic Sealer

- Electrophoretic Lacquer—among the purest and most potent botanicals

- Spray Lacquer with Electrostatic Technology

- Zamac Die Casting Equipment

- Plant Electroplating and Anodizing Using Ultrasonic Degreasing

- polishing with a range of coatings

- Computerized Numerical Control in Powder Coating Wire Cut Machine C.N.C.

- Polybag Packing Machine with Automatic Function

Product Development expertise

The company is endeavoring to develop new products, and with a team of highly technical & skilled staff; it is committed to satisfying customers by continual improvement in product quality & services.

- Research and Tooling department

- Custom product development through AutoCAD software

- Testing Lab

Environment Conscious

We at Sunshine Metal Industries believe in the sustainable development of the earth and its surroundings for our future generations. Environmental issues are cumulating every day, including major problems associated with water management from industrial waste. Subsequently, we have taken curative actions to protect the environment by implementing measures like:

- Effluent Treatment Plant (ETP)

- Safety, Health, and Environment Policy

- Periodic initiatives and campaigns to encourage Forestation and rainwater Harvesting